|

A

Citroën company, the Citroën Gear Company was set up in England before

the First World War and marketed heavy industrial gearing. In 1919, the

Citroën factory in France exported 750 cars to Britain where they were

sold in the London area by the Citroën concessionaire, Gaston Limited.

By the end of 1921, the company had sold a total of 2 451 vehicles. By

1923, there were over 23 000 Citroëns on British roads. Gastons found

this level of business difficult to service so in 1923, Citroën Cars

Limited was set up in London with its headquarters in the Citroën

Building, Brook Green, Hammersmith to take over the import and

distribution of Citroën vehicles throughout the country.

The

rising demand for the vehicles and the imposition of the McKenna Duties

on imported vehicles led André Citroën to set up an assembly plant to

manufacture cars for the British domestic and Empire (later

Commonwealth) markets where right hand drive cars were the norm. The

Citroën factory, in the Slough Trading Estate was opened on 18th

February 1926 and was to continue building cars until 1965 when the

operation became dedicated to sales and marketing.

Not

only were the cars built with right hand drive steering, they were

frequently renamed and equipped with extras not fitted to the domestic

market vehicles.

One

of the rarest of all production Citroëns was the Slough-built, 2

CV-based Bijou.

|

|

THE AUTOCAR, February 19th, 1926

HOME-PRODUCED FOREIGN CARS.

McKenna Duties Lead to Plans for Manufacturing

Continental Products in this Country on a Large Scale.

AFTER the reimposition of the McKenna

Duties,

it was evident that the manufacturers of the most popular Continental

products would arrange to assemble cars in special works in this

country. The advantage of this practice to this country in general is

obvious, owing to the large number of British hands who would find

employment.

|

|

|

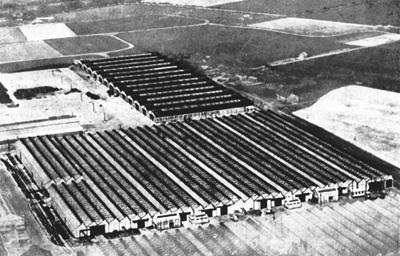

The

Citroën venture at Slough, for example, is a very good instance in the

case. There are at the present moment two shops, one of 300,000 square.

feet floor space, the other of 200,000 square feet, the former,

therefore, being one of the largest shops in the British Isles. There

are 60 acres of ground, which can be used for further development. The

very latest pattern of moving platform or chain conveyor has been

erected in the shops and is used for assembling the various types of

Citroën, the parts, of course, being supplied from the Citroën factory

in Paris. The whole of the bodywork is also assembled at this shop,and

steps are being taken to manufacture the all~steel saloon which was

exhibited at the last Olympia Show, where it created considerable

interest.

Special Plant for Quick Assembly.

There are special ovens for the painting system, and compressed air

plant of a design later even than that used for the principal factories

in America has been installed to run the drills and mechanical spanners

used in the assembly shop. The components, of course, are erected

separately and fitted to the chassis as it proceeds slowly on the

conveyor, the bare frame being put on, as it were, at one end, the

finished car running off the conveyor at the other. There is a new and

very elaborate system for nickel-plating various parts of the car, and

it is interesting to note that a plant has been installed for dealing

with the plate glass used for windscreens and windows. Into the works

runs a siding from the main Great Western line, so that material can be

received, and chassis sent away, without interruption.

The

works are not yet running at full capacity, but when complete will find

employment for about 5,000 operatives. At the present moment the latest

type of 11.4 h.p. Citroën chassis is being erected, this ,having

appeared at the Brussels Show; and, of course, in France. The principal

difference between the latest model and its predecessors is the

provision of front wheel brakes operating in conjunction‘,with the

brakes on the rear axle, and of special design, with the cam actuating

shaft and cam at the lowest point of the brake drum. Dumb-irons and

half-elliptic springs have replaced the abbreviated frame

quarter-elliptics hitherto used.

Another Continental

firm producing well-known and popular cars for the British market is

getting ready to develop an assembly plant of considerable size, while

the Michelin Tyre Company, as has already been announced in our

columns, are preparing to organise a large factory at Stoke-on-Trent

for the purpose of manufacturing tyres for the British market.

|