|

|

|

The Citroën C5

is an all-round innovator, featuring new solutions in

the key areas of

safety, comfort, driving pleasure, environmental

sensitivity and

running costs.

With

respect to active safety, note the 3rd generation

Hydractive

suspension, ABS anti-lock braking, ASR accereration

slip reduction,

assisted emergency braking, the low tyre pressure

warning sensors and

the lively, responsive nature of the engines and

semi-automatic

sequential transmission.

To provide

maximum passenger protection, the C5 is based on a new

platform incorporating:

-

six airbags

of which two at the front adapt to the violence of

impact,

-

front and

rear seatbelts with force limiters,

-

front doors

with impact bars and padding.

For

comfort and driving pleasure, note the spacious cabin,

the multiplex

electronic circuitry and the additional functions it

provides, the

damping of vibration and noise, and 'of course' the

engines and

sequential automatic gearbox.

Citroën's

commitment to protecting the environment is reflected

in the presence

of a particle filter (on models fitted with the 2.2

HDi engine),

reduced fuel consumption, lower CO2 emissions (all

engines) and the use

of recycled materials.

|

Technical

characteristics

|

|

|

Running gear

The C5 has a

new suspension system combining advanced electronic

and hydraulic technology

Highlighting

significant progress in suspension system design,

Citroën has equipped the C5 with 3rd

generation Hydractive,

the hydraulic suspension unveiled and demonstrated at

the Geneva Motor

Show. This system is key to the roadholding / ride

comfort balance, a

factor that is essential to active safety and driving

pleasure.

The 3rd

generation Hydractive suspension system comprises :

-

a

BHI ("Built-in Hydroelectronic Interface"), the

core of a system that

incorporates a powerful control unit, an

autonomous hydraulic pressure

generator (pump and electrovalves with hydraulic

distribution) and an

electric motor,

-

four carrier

elements with new suspension spheres,

-

front and

rear ride height regulators front and rear,

-

electric

height sensors linked to the anti-roll bars,

-

fluid

reservoir,

-

a simplified

hydraulic network with new-generation connections,

-

and a

control function and position indicator on the

multifunction screen.

This

simplified but innovative concept is based on the

latest advances in

electronic and hydraulic technology, featured by the

BHI. The main

characteristics are as follows.

Automatic

ride height adjustment depending on vehicle speed

and road surface

This technical

innovation enhances comfort and safety in all

circumstances by adjusting vehicle height on three

levels :

-

in town and

on well surfaced roads at speeds of up to 110

km/h, the car’s ride height remains standard ;

-

at

speeds of more than 110 km/h on well surfaced

roads, the BHI lowers the

front of the car by 15 mm and the rear by 11 mm.

This improves vehicle

stability by lowering its centre of gravity,

lowers fuel consumption by

reducing drag and makes the car less sensitive to

crosswinds. The car

returns to its standard ride height when speed

drops below 90 km/h ;

-

on

poorly surfaced roads, the BHI raises the

vehicle’s ride height to

increase clearance without compromising handling

or comfort. If the

road is in particularly poor condition, the height

is raised by 13 mm –

provided that the car is travelling at less than

70 km/h.

In

order to determine the most appropriate ride height,

the BHI monitors

data on vehicle speed and on the height and movement

of the suspension.

The car is raised or lowered by adding or removing

hydraulic fluid to

or from the suspension circuitry.

The driver can

also adjust vehicle height manually. Four settings are

available through an electronic pulse control system :

H : high -

the maximum height setting, to be used when changing a

wheel.

P

: raised - an intermediate setting designed for

clearing obstacles at

low speed. The clearance increases by 40mm in this

instance.

N : normal

- for ordinary driving conditions.

B : low -

the minimum possible setting to facilitate loading and

the coupling of trailers or caravans.

These positions

are displayed on the multifunction screen.

The

control system has an electronic safety device to

prevent unsuitable

settings being selected. The "high" option is not

available when the

car is travelling faster than 10 km/h and "raised"

mode cannot be

selected after 40 km/h.

The

3rd generation Hydractive suspension makes full use of

the advantages

offered by hydraulic technology, such as standard ride

height

regardless of vehicle load.

|

Auto-adaptive

suspension

3rd

generation Hydractive suspension adapts automatically,

instantly and

continuously to suit individual driving styles and the

state of the

road. It incorporates two settings, comfort and sport,

which can be

selected by adjusting the damper settings. Each axle

features a third

sphere (for flexibility) and a stiffness regulator

(controlling damper

settings and switchover to the supplementary sphere).

The system is

designed to isolate these elements in "sport" mode and

activate them in

"comfort" mode in response to the signals received

from the ride height

sensors and steering wheel, plus the data on brake

pressure and engine

revs captured by the multiplex network.

In

addition, the longitudinal and lateral acceleration

data calculated by

the BHI are collected and filtered over a period of

around one minute.

The

"auto-adaptive" characteristics of the suspension

allow it to identify

individual driving styles. The more vigorous the

driving technique, the

faster the suspension will transfer to sport mode and

thus become

personalised to suit the driver.

The driver can

express a preference for "sport" mode using a switch

on the instrument panel.

Suspension

characteristics

The

BHI ("Built-in Hydroelectronic Interface") features

the latest

electronic and hydraulic technology. The compact unit

comprises three

parts :

a

control unit with a host of control laws stored in its

memory,

controlling the electric motor and the stand-alone

pressure generator

in accordance with the information delivered by :

-

two

new electric height sensors positioned on the

front and rear anti-roll

bars, which take precise measurements on

variations in the body’s

height and rate of movement,

-

a

sensor measuring the steering wheel angle and the

speed at which it is

turning,information on the rate of throttle

application (or

deactivation), vehicle speed, brake pedal pressure

and engine speed ;

-

an

electric motor to power the pump housed in the

stand-alone pressure

generator. Active only when necessary, it operates

independently of

engine speed at 2,300 rpm;

-

a

stand-alone pressure generator houses all the

safety, output and

anti-dive controls. It incorporates a pump and

four electrovalves.

The

five-piston pump supplies fluid (0.7 litres per minute

at 2,300 rpm)

and operates at pressure of between 80 and 140 bars.

At the end of the

pump, a hydropneumatic accumulator evens out pressure

pulsations and

keeps noise levels to a minimum.

The

suspension circuitry has two electrovalves, front and

rear, one for the

hydraulic fluid intake, the other for the fluid

exhaust. The intake

electrovalves are equipped with a non-return valve.

Electromagnetic

force ensures an operational response that is almost

instantaneous (17

ms).

The

spheres are fitted with new multi-layer diaphragms

that are not

nitrogen-permeable. The pressure of the nitrogen

(calibration) in the

spheres therefore remains constant over time, ensuring

that the

suspension maintains all its properties.

The

new exterior shape of the spheres (modified diameter /

height ratio)

has been optimised by computer calculations for a

longer service life.

The

new hydraulic fluid is 100% synthetic. This

composition gives it

long-term stability while maintaining a high level of

viscosity (low

friction).

All

the parts used by 3rd generation Hydractive suspension

are of high

quality, manufactured and assembled in extremely clean

conditions. The

system requires requires no maintenance for the first

five years or

200,000 km.

|

|

|

3,0i

V6

Manual

|

3,0i

V6

Automatic

|

2,2

HDi

Manual

|

2,2

HDi

Automatic

|

|

Front

|

Comfort

|

Sport

|

Comfort

|

Sport

|

Comfort

|

Sport

|

Comfort

|

Sport

|

|

Spring

rate

(mm/100kg)

|

|

|

|

|

|

|

|

|

|

|

116

|

73

|

108

|

68

|

114

|

71

|

110

|

61

|

|

|

93

|

59

|

88

|

55

|

92

|

58

|

89

|

56

|

|

Frequency

(Hz)

|

|

|

|

|

|

|

|

|

|

|

0,69

|

0,88

|

0,70

|

0,89

|

0,70

|

0,88

|

0,71

|

0,89

|

|

|

0,73

|

0,92

|

0,74

|

0,94

|

0,73

|

0,93

|

0,74

|

0,94

|

|

Rear

|

|

|

|

|

|

|

|

|

|

Spring

rate

(mm/100kg)

|

|

|

|

|

|

|

|

|

|

|

240

|

127

|

240

|

127

|

247

|

131

|

247

|

131

|

|

|

117

|

62

|

117

|

62

|

120

|

63

|

120

|

63

|

|

Frequency

(Hz)

|

|

|

|

|

|

|

|

|

|

|

0,67

|

0,91

|

0,67

|

0,91

|

0,66

|

0,90

|

0,66

|

0,90

|

|

|

0,80

|

1,09

|

0,80

|

1,09

|

0,79

|

1,09

|

0,79

|

1,09

|

|

|

Front

suspension

The

hydraulic front suspension features a MacPherson-type

set-up. It

comprises a sub-frame attached to the body in four

places by new

flexible mountings, designed to filter vibration from

the road, new

forged steel wishbones, iron pivots and an anti-roll

bar linked

directly to the strut bodies by rods.

|

|

|

Rear

suspension

The

innovative rear suspension features an innovative

cross-beam with cast

iron trailing arms, self-steering elastic bushes and

an anti-roll bar.

The

cross-beam comprises an aluminium section with cast

aluminium supports

welded on at either end. This concept is 13 kg lighter

than more

conventional suspension systems. And it also creates

less vibration.

Attached

to the trailing arms and axle supports, the

sphere-bearing carrier

elements are horizontal to avoid any part of the axle

assembly

intruding into the designated load area. This ensures

the best possible

use of space to maximise boot capacity.

|

|

|

3,0i

V6

|

2,2

HDi

|

|

Front

axle

|

|

|

|

Castor

angle (°)

|

3

|

3

|

|

Camber

angle (°)

|

0

|

0

|

|

Alignment

(mm)

|

1,5

|

1,5

|

|

Track

(mm)

|

1 528

|

1 530

|

|

Anti-roll

bar diameter (mm)

|

23,5

|

23,5

|

|

Roll

Radius

|

3

|

2,5

|

|

Rear

Axle

|

|

|

|

Camber

angle (°)

|

1

|

1

|

|

Alignment

(mm)

|

4

|

4

|

|

Track

(mm)

|

1 493

|

1 495

|

|

Anti-roll

bar diameter (mm)

|

21,5

|

21,5

|

|

|

|

Wheels and

tyres

The

C5 features cast aluminium wheels in either 15- or

16-inch diameter.

The 2.2 HDi version is fitted with "Imola" aluminium

wheels and 205 /

65 R15 H tyres, at trim level 2, or "Monza" aluminium

wheels and 215 /

55 R16 W tyres at trim level 3. These last tyres are

also standard on

models powered by the 3.0i V6.A full-size spare wheel

is housed within

the rear floor.

Low tyre

pressure warning system

A

sensor-transmitter, located within each tyre valve,

sends a continuous

high-frequency signal to a receiver housed within the

upper part of the

steering column in order to monitor tyre pressure. If

the pressure

drops more than 0.3 bar below the recommended standard

setting, the

driver is alerted by an audible alarm and a message on

the

multifunction display unit.

Brakes

All

C5 models are fitted with ABS anti-lock braking and

EBD (electronic

brakeforce distribution), as well as emergency braking

aids and

automatic engagement of the hazard warning lights.

Operating

independently from the suspension, the braking system

is of

conventional design with its X-shaped layout, master

cylinder,

amplifier and the use of discs all round (ventilated

at the front,

solid at the rear).

Emergency

braking assistance

In

the event of an emergency, many motorists do not

instantly apply

sufficient pressure to the brake pedal. In these

circumstances,

Citroën’s emergency braking assistance increases brake

pressure in

relation to the speed at which the pedal is applied.

When the car is

travelling at 100 km/h, stopping distance is reduced

by 25 per cent.

Twin pistons located upstream of the emergency system

actuate the

process mechanically. When the brake pedal is pressed

at a speed faster

than 450 mm / s2, the primary piston sets off a

secondary piston that

exerts maximum pressure on the braking system up to

the point that the

ABS comes in.

Considerable

attention has been paid to the ergonomy and

progressiveness of the

parking brake, which operates on the front wheels.

The same

reservoir is used to house brake fluid and supply the

hydraulic clutch system.

|

|

|

3,0i

V6 and 2,2 HDi

|

|

Type

|

X-shaped

|

|

Effort

reduction ratio

|

6,6

|

|

Master

cylinder diameter (mm)

|

22,2

|

|

Front

brakes

|

Ventilated

discs

|

|

Disc

diameter (mm)

|

288

|

|

Disc

thickness (mm)

|

28

|

|

Brake

lining surface area (cm2)

|

62,6

|

|

Piston

diameter (mm)

|

57

|

|

Rear

brakes

|

Solid

discs

|

|

Disc

diameter (mm)

|

276

|

|

Disc

thickness (mm)

|

14

|

|

Brake

lining surface area (cm2)

|

29

|

|

Piston

diameter (mm)

|

32

|

|

Automatic

hazard warning lights

The

ECU in the ABS system calculates the rate of

deceleration and, once a

certain threshold has been reached, activates the

hazard warning lights

via the BSI.

Acceleration

slip reduction (ASR)

The C5 has an

acceleration slip reduction (ASR) system.

The

ABS computer uses the wheel sensors to assess the

possibility of

wheelspin whenever the car pulls away on a low-grip

surface, and

automatically brakes the wheel (or wheels) concerned.

|

|

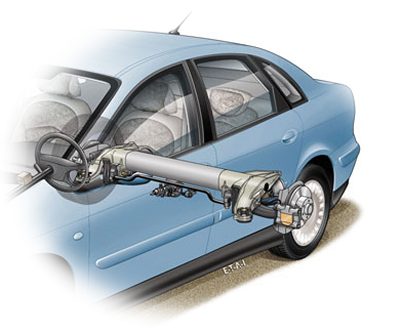

Steering

The

C5 is fitted with hydraulic variable-assistance power

steering with a

built-in ram, totally independent of the suspension.

Variable power is

provided by an engine-driven hydraulic pump that

reduces flowrate

progressively as the engine speed increases. This

means steering is

lighter at low engine speeds (when parking for

example) but firms up at

high speed.

Maximum

steering assistance is provided at engine speeds of

between 600 and 1

000 rpm, with a pump flowrate of 10 l / min.

Assistance falls off

steadily as engine speed rises, with a pump flowrate

of 6 l / min at 2

600 rpm.

In models fitted

with the 3.0i V6 engine, variable-assistance power

steering is determined directly by vehicle speed.

An

electronic controller adapts the level of pressure in

the hydraulic

circuit in accordance with a predefined profile

controlled by a

solenoid valve.

The

steering column is height-adjustable through 40 mm and

reach-adjustable

through 27 mm. The column will collapse progressively

in the event of

impact and is damped to absorb vibration before it

reaches the driver.

|

|

©

2000 Julian Marsh/Citroënët/SA Automobiles Citroën |

|

|