1955 Autocar review of Citroën DS19

|

|

|

|

Citroen DS19 Startles Paris

NEW MODEL

BRISTLES WITH ORIGINAL FEATURES

|

|

THE 11 c.v. Citroen has been in production

for twenty-one years without any basic changes. It was a fairly

short-odds bet, therefore, that when it was replaced the new car would

be equally advanced in its conception, and the impact which the new D

l9 made at its presentation the night before the Paris Salon was opened

was quite staggering. It will take some time to prove whether the

innovations offered will be acceptable to the buying public.

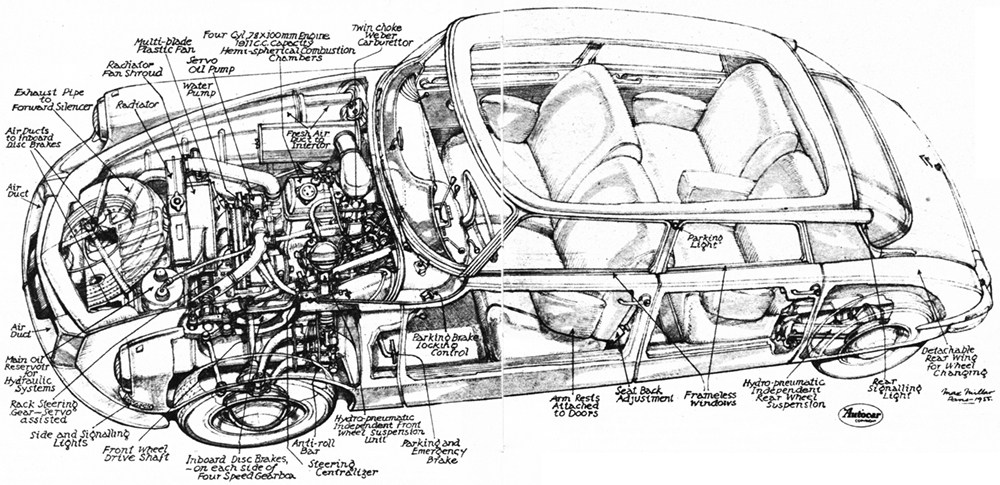

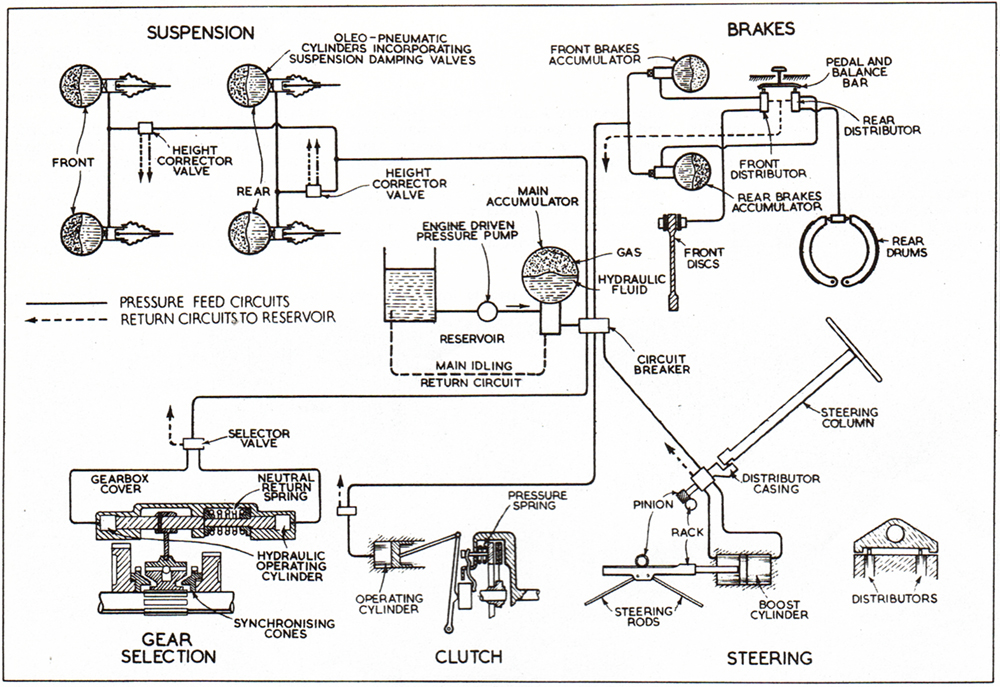

There is a complicated system of hydraulics,

controlled from a master pressure pump and accumulator. The system is

ingenious, but there is a complementary degree of complication which

may present problems in maintenance.

The new model retains the same basic layout

as previously, with reversed engine and front wheel drive. A

constant-layshaft type of gear box is used, as hitherto, in which the

drive shaft £rom the clutch passes over the differential assembly

mounted on the end of the second motion shaft. The drive shaft to the

wheels uses a double Hooke type universal joint, placed back to back

also as hitherto.

|

|

Hydraulic Circuits

A belt-driven hydraulic pump and reservoir

feeds an elaborate hydraulic system used for the four-wheel

oleopneumatic independent suspension, which is similar to that fitted to

the rear end only of the six-cylinder 15H model, now taken out of

production. A full description of this system was given in The Autocar

of August l9, 1955. Other circuits supply hydraulic power for operation

of the four-speed gear box and clutch, which are controlled by a single

change-speed lever on the dash. The clutch pedal has, therefore,

disappeared and clutch action begins automatically at the moment of

gear change.

Another circuit operates the brakes. These

are inboard discs at the front, and normal drums with leading and

trailing shoes at the rear. Finally the rack and pinion steering is

hydraulically assisted by a booster cylinder on the end of the rack,

controlled by a two-way valve on the steering column.

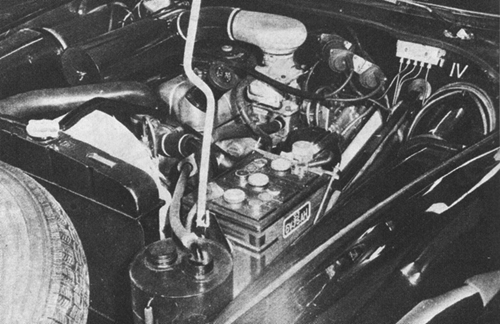

The four-cylinder power unit incorporates a

new aluminium cylinder head on the previous D-model cylinder block and

crankcase. It has a bore of 78 mm and stroke of 100 mm (1,911 c.c.) and

develops 75 b.h.p. at 4,500 r.p.m. with a compression ratio of 7.5 to

1. The combustion chamber is hemispherical and the valves, with an

included angle of 60 degrees, are operated by long and short rockers

actuated by push rods from the single camshaft mounted in the

crankcase. The layout is similar to that used on the Peugeot and the

Armstrong Siddeley Sapphire.

|

|

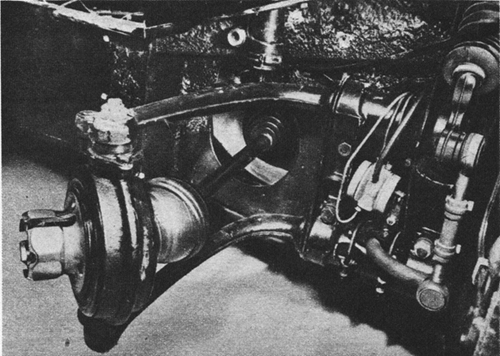

Front

suspension is by two forward facing half-wishbone forged steel arms.

The wheels pivot on

balls attached to the end of each arm. A lever on the inboard end of

each top arm operates the

oleo-pneumatic suspension unit. From the same lever a drop link

connects to the transverse tor-

sion bar which also incorporates the static height corrector valve

|

|

A double-choke downdraught Weber carburettor

is used and the induction manifold is water-jacketed for induction

pre-heating. A twin V belt takes the drive from a pulley on the end of

the camshaft to the dynamo and water pump, on the end of which is an

eight-bladed fan moulded in nylon and running in a ducted cowl behind

the radiator. The hydraulic Pressure pump is driven by a single belt

from the same camshaft pulley.

Trailing arms are used for the rear

suspension, with a drop arm lever at their pivot points connecting to

the suspension cylinders. There is an anti-roll bar connected between

the two pivot bearings. At the centre of the anti-roll bar, on the

point of neutral twist, is a rod which connects to the control valve of

the height corrector. This valve controls the flow of oil into the strut

of the suspension cylinders so that the static height of the car

remains the same irrespective of load.

Oleo-pneumatic cylinders are also used for

the front suspension. There are two L-shaped arms top and bottom which,

in effect, are each one half of an orthodox wishbone system. They

extend forward from two longitudinal bearings which are bolted in one

assembly to the frame side members at the scuttle structure. At their

outer ends they swivel on balls for wheel movement.

At the rear end of the top arm bearing is a

lever attached to the end of the arm. It connects to the lower end of

the oleopneumatic strut and also carries a drop link which is connected

to the ends of a transverse anti-roll bar. From the neutral point of

this torsion bar is a rod connecting to the static height corrector

valve, in the same way as in the rear suspension.

The wheels are fixed to the hubs by one

central bolt retained in the wheel by a circlip. The drive is taken

through a hexagonal member on the outside of the wheel hub, mating with

a corresponding ferrule depression formed in the wheel hub. The front

tyres are larger in section than the rear since the loads are

considerably higher, an estimate of the ratio being 65 per cent front

and 35 per cent rear. Front tyre size is 165 x 400 mm (approx.

6.50—-16in) and at the rear 155 x 400 mm (approx. 6.00—16in). The spare

wheel, which is mounted in front of the radiator, is 165-400 mm — the

same size as the front - but it could be used on the rear in an

emergency.

Disc brakes are used at the front and are

mounted inboard at the final drive unit in a similar manner to those of

the 2 c.v. Normal leading and trailing shoe brakes with their drums

mounted at the wheels are used at the rear. Both are operated

hydraulically from the main servo system, the operating pedal being a

plunger with a circular pad of only about 1 ¾ in diameter. The

operational travel is very small as it is required only to open the

distribution valves, which are actuated by a balance bar attached to

the pedal.

There is one distribution valve for each of

the front and rear brake circuits, and similarly one small accumulator

for each, taken off the main accumulator circuit. Depression of the

pedal opens the valves and oil under pressure is fed from the

accumulators to each circuit. The brake pedal load will be almost

negligible under these conditions and would be expected to lack feel.

The front disc brakes are cooled by air

inlets for the front, and have automatic adjustment for wear. The

braking system allows for varying load conditions, which means that,

irrespective of the load carried and transference to the front

resulting from it, the braking will be compensated for this condition.

|

|

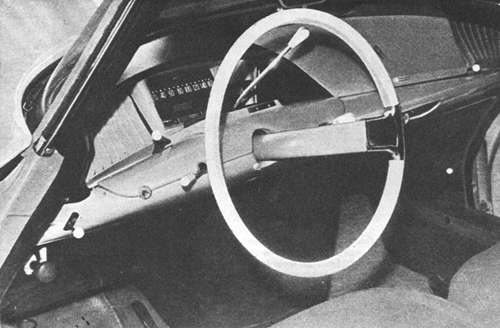

No parking brake lever is provided; instead

a large pedal on the driver's extreme left doubles as parking and

emergency brake. It is connected to the front brakes by a mechanical

linkage and is thus available for emergency use in the event of failure

of the main hydraulic system. For parking the pedal is depressed and

then locked down with the aid of a knob below the facia. The knob

itself has a safety catch.

The steering wheel is of very unusual design

in that it has only one spoke, formed by bending the steering column

over into the wheel rim. Towards the rack end, the steering column is

split and provided with a flattened face on each of the halves. These

two faces overlap. In the lower half are two distributor valves, one

for each direction of turn, which circuit the main oil pressure to

either side of a booster cylinder attached to the end of the rack. In

the event of hydraulic failure mechanical connection is effected by the

two_ flattened faces of each half in the steering column joint.

Hydraulic assistance will considerably lighten the steering loads,

which are otherwise heavy owing to the disproportionate weight

distribution of a front-wheel-drive layout.

Synchromesh is provided on the top three

ratios of the four speed box. Operation is hydraulic, in conjunction

with the clutch release, which is incorporated in the change-speed

lever. The gear lever is merely moved into the required gear and clutch

operation is automatically combined with this movement. It has not been

possible to analyse this circuit, but there is some sort of override

mechanism on the throttle linkage as there are two slip links

incorporated in it.

|

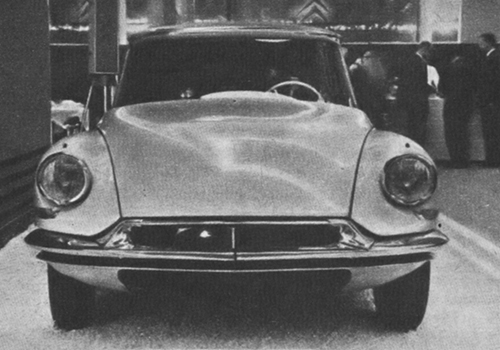

The shallow

mouth of the new DSI9 has an intake on either side of the main intake

to duct cold air to the inboard disc brakes

|

|

Thus the foot throttle is overridden,

irrespective of its position,

and the throttle setting automatically adjusted to give the required

engine speed for the gear change. It is necessary to move through the

gears progressively, i.e., a change cannot be made direct from top to

second without going through third.

The clutch is of the normal single dry plate type without centrifugal

action, which is common practice when the clutch pedal is discarded.

The clutch plates are held in the drive position by springs, released

by hydraulic actuation from gear lever. There is a control sensitive to

engine speed to release the clutch below a set minimum speed when

idling. It is a hydraulic governor in tandem with the water pump and

connected to the selector mechanism. There is a manual override control

on the facia to put the automatic clutch out of action when the engine

is stationary. By this means the engine can be tow started.

|

|

|

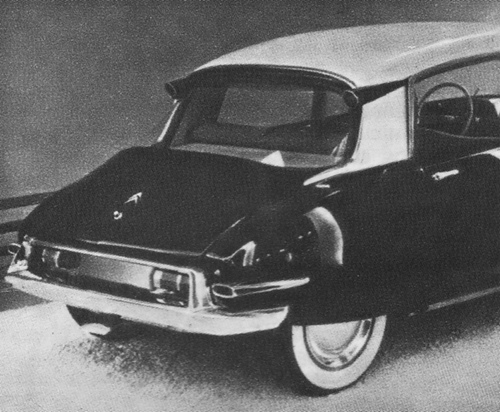

Above

The steering column, bent to form a single spoke, is unusual. Gear

selection and clutch operation are combined in a single lever above the

steering wheel. Facia panels are rather thin plastic

Left

Rear overhang is short but luggage accommodation is good. Flashing

indicators are mounted

high at the extremities of the rear windows

|

|

|

Integral construction is used on the same

lines as the previous cars, with deep side members formed by the body

sills and front suspension. Power unit loads are carried on the forward

bearer arms and braced into the scuttle structure.

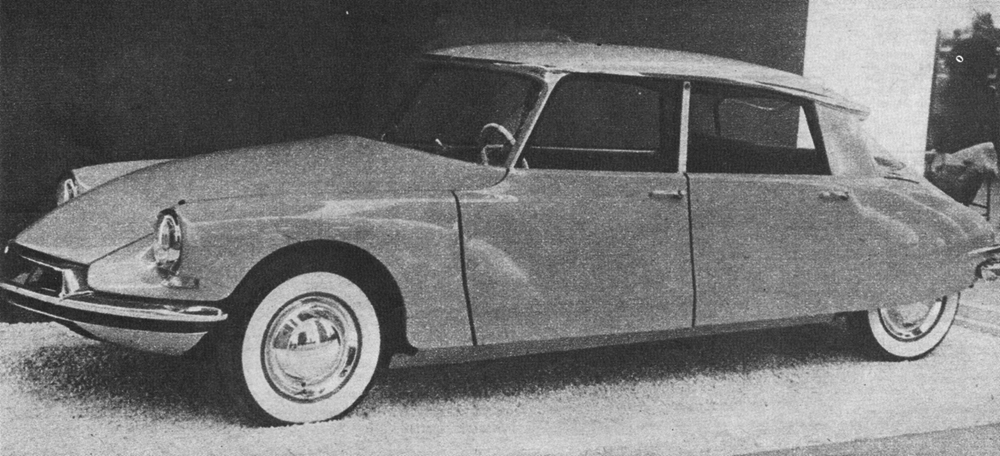

The outline of the car is long and low, with

very little overhang at the rear; the Italian firm of Bertone (incorrect

– Flaminio Bertoni – unrelated to Bertone - was employed by Citroën)

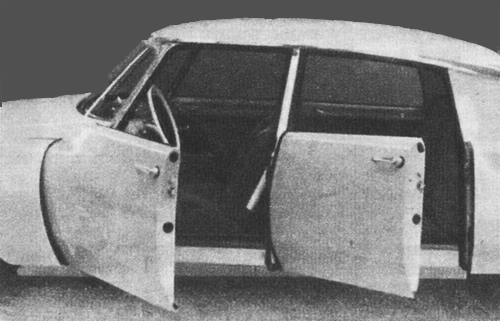

were enlisted on the design side. The windscreen is curved well round

to provide excellent vision and the screen pillars are very thin, a

thinness which is helped by the fact that the doors have no window

frames. The glass of the door windows seals against flexible rubber

strips attached to the body. The new model has winking indicators in

the belled-out rear ends of the chrome mouldings which extend rearward,

above the frameless windows, from the top of the curved screen. The

roof panel is plastic.

|

|

Those

who recall the same stylist’s Bristol model will not be surprised to

learn that Bertone was responsible for the new Citroen styling

|

|

|

There are no

window frames above the doors, the glass sealing on flexible rubber

strips attached to the body framework

|

The

hemispherical head has a Weber double-choke downdraught carburettor.

Two coils with

twin contact breakers are used for the ignition.Some of the maze of

pipeline can be discerned

|

|

The rear track is narrower than the front by

7 3/4in, and the body form follows its general shape with the

noticeably greater width at the front. For its size the wheelbase is

exceptionally long at 10ft 3in, which is l 1/2in more than the present

range. Although the overhang at the rear is short the overall length is

15ft 9in. Similarly, the front track is 1/2in wider at 4ft llin, but -

which is more important-—-the turning circle has been reduced to 36ft

lin (as opposed to 45ft 6in), which considerably improves

manoeuvrability, which was always a point of criticism on the Citroen.

It is difficult to assess at the moment what

sort of reception the car will receive. It moves into a higher price

bracket than previous Citroen models by approximately £150. It is

bristling with ingenious features, but they are, of necessity, rather

complex, and the maze of hydraulic pipes with their circuits, dependent

upon one belt-driven hydraulic pump, may result in some apprehension on

the part of would-be purchasers, and this might affect its initial

commercial success.

|

|

Engine.—4-cyl,

78 mm bore X 100 mm stroke (3.1 ><'3.9in), 1,911 c.c. (116.5 cu

in).

Compression ratio, 7.5 to 1. 75 b.h.p. at 4,500 r.p.m. Maximum torque,

101 lb/ft. Double-bodied Weber downdraught carburettor. Pump and

thermostat, nylon fan, cooling.

Clutch.—Single

dry plate. Automatic hydraulic control.

Transmission.—Four-speed

with synchromesh on second, third and top. Hydraulic control. Front

wheel drive, spiral bevel final drive. Gear change lever under steering

wheel (this is incorrect, it is above the steering wheel).

Suspension.—Front,

independent, oleopneumatic with anti-roll bar and static height

corrector. Rear, independent, oleopneumatic with anti-roll bar and

static height corrector.

Brakes.—Disc

brakes for the front wheels, drum brakes for the rear wheels. Pressure

distributed according to axle loading. Automatic adjustment on front

brakes. Total brake lining area, 80.6 sq in.

Steering.—Rack

and pinion. Hydraulically assisted.

Wheels and

Tyres.—Central

fixing for wheels. Michelin 155-400 tyres rear, 165-400 front and on

spare wheel. English models have 165x400 tyres all round.

Fuel

System.—14-gallon fuel tank. Mechanical feed pump. Oil capacity

7 pints.

Electrical

System.—l2-volt S7 ampere-hour battery (6-volt system in France).

Main

Dimensions.—Wheelbase,

10ft 3in. Track, front, 4ft llin; rear, 4ft 3 1/4in. Overall length,

15ft 9in. Width, 5ft 10 1/2in. Height, 4ft 10in. Turning circle, 36ft

1in. Dry weight, 2,464lb (22cwt).

Performance.—Top

speed on level, 87 m.p.h.; maximum speed in third, 72 m.p.h.; maximum

speed in second, 50 m.p.h.; maximum speed in first, 25 m.p.h.

Price.—Basic,

£990, plus £413 12s 6d U.K. purchase tax; total, £1,403 12: 6d.

|

|

|

|

| ©

2017 Citroënët/1955

Autocar |

|

|