|

||||||||||||||||||||||

Wankel Rotary Engine

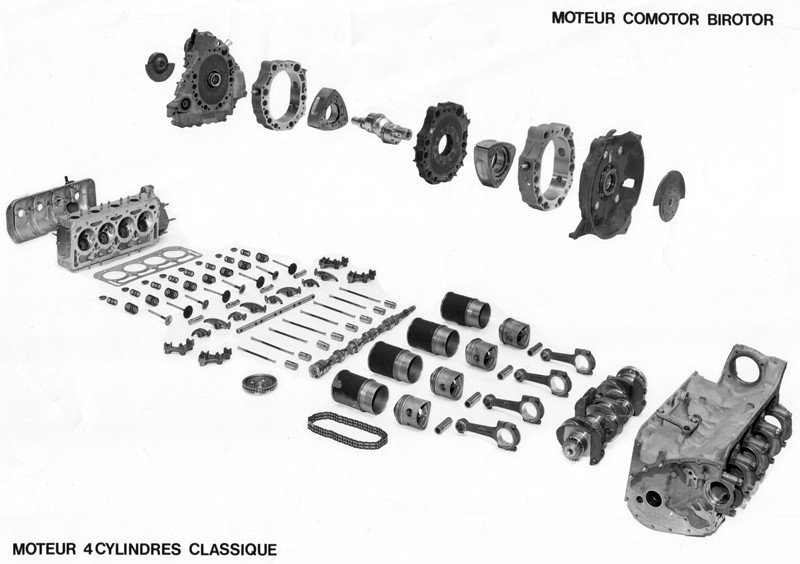

Problems with gas tightness, exhaust emissions and high fuel consumption which also coincided with both the Middle East oil crisis and the Peugeot take over led to the abandonment of the Wankel project by Citroën. The Ro80 soldiered on for a few more years and nowadays, only Mazda builds Wankel powered cars, having solved the rotor tip wear problems. Mercedes Benz, Rolls Royce and GM have all investigated the Wankel engine but the reality sadly did not meet expectations. In theory, a rotary engine should be turbine smooth and much more efficient than a conventional engine. Furthermore, the number of moving components is greatly reduced in comparison to a conventional engine while the total number of components is approximately ten per cent of those in a normal engine. This results in a considerable reduction in weight, an improvement in efficiency and a reduction in manufacturing costs. Certainly power outputs were considerably greater than an equivalent capacity reciprocating engine - the swept volume figures quoted here are actually double those of the actual cubic capacity; thus the M35 engine was really 497 cm3 and the Birotor was 995 cm3 . The engines were indeed much smoother than conventional engines and were willing to rev quite freely - indeed it was felt necessary to fit both a warning buzzer and an ignition cut out to prevent over revving. The prime shortcomings were an almost linear torque curve (which meant that both the Ro80 and Birotor had to be fitted with semi automatic gearboxes equipped with a torque converter to allow for torque multiplication at low engine speeds) and excessive rotor tip wear which led to high oil and fuel consumption, loss of power and high emissions. With modern technology and electronic controls, the engine can be made to work reliably and is extremely attractive but high fuel consumption remains a bugbear. In the seventies, the technology was simply not up to the task. Had the engine been made to work efficiently, it is likely that it would have provided the power source for the CX; in the event, the CX was initially fitted with the engines from the DS. NSU was absorbed within the Volkswagen/Audi group and Citroën within the Peugeot group. |

|

|||||||||||||

Click for large image below - comparison between Wankel rotary engine and a conventional 4 cylinder engine |

||||||||||||||

|

||||||||||||||

|

||||||||||||||

|

Above the Citroën helicopter project initiated in the late 1960s was fitted with a twin-rotor Wankel rotary engine developing 180 bhp, the helicopter made several hundred flights and had a top speed of over 200 km/h but when production of the Wankel ended in 1979, the project came to an end. |

||||||||||||||

|

||||||||||||||

| The four pictures above showing the two Citroën production Wankel-engined cars, the M35 and Birotor are © Klaus Nahr | ||||||||||||||

| © 1999 Julian Marsh/Citroënët | ||||||||||||||